TRANSFORM

A series of transformations are applied to the Life Cycle Inventory (LCI) database to align process performance and technology market shares with the outputs from the Integrated Assessment Model (IAM) scenario.

Biomass

Run

from premise import *

import brightway2 as bw

bw.projects.set_current("my_project)

ndb = NewDatabase(

scenarios=[

{"model":"remind", "pathway":"SSP2-Base", "year":2028}

],

source_db="ecoinvent 3.7 cutoff",

source_version="3.7.1",

key='xxxxxxxxxxxxxxxxxxxxxxxxx'

)

ndb.update("biomass")

Regional biomass markets

premise creates regional markets for biomass which is meant to be used as fuel in biomass-fired powerplants or heat generators. Originally in ecoinvent, the biomass being supplied to biomass-fired powerplants is “purpose grown” biomass that originate forestry activities (called “market for wood chips” in ecoinvent). While this type of biomass is suitable for such purpose, it is considered a co-product of the forestry activity, and bears a share of the environmental burden of the process it originates from (notably the land footprint, emissions, potential use of chemicals, etc.).

However, not all the biomass projected to be used in IAM scenarios is “purpose grown”. In fact, significant shares are expected to originate from forestry residues. In such cases, the environmental burden of the forestry activity is entirely allocated to the determining product (e.g., timber), not to the residue, which comes “free of burden”.

Hence, premise creates average regional markets for biomass, which represents the average shares of “purpose grown” and “residual” biomass being fed to biomass-fired powerplants.

The following market is created for each IAM region:

market name

location

market for biomass, used as fuel

all IAM regions

inside of which, the shares of “purpose grown” and “residual” biomass is represented by the following activities:

name in premise |

name in REMIND |

name in IMAGE |

name in LCI database |

|---|---|---|---|

biomass - purpose grown |

SE|Electricity|Biomass|Energy Crops |

Primary Energy|Biomass|Energy Crops |

market for wood chips |

biomass - residual |

SE|Electricity|Biomass|Residues |

Primary Energy|Biomass|Residues |

supply of forest residue |

The sum of those shares equal 1. The activity “supply of forest residue” includes the energy, embodied biogenic CO2, transport and associated emissions to chip the residual biomass and transport it to the powerplant, but no other forestry-related burden is included.

Note

You can check the share of residual biomass used for power generation assumed in your scenarios by generating a scenario summary report.

Note

When running premise with the consequential method, the biomass market is only composed of purpose-grown biomass. This is because the residual biomass cannot be considered a marginal supplier for an increase in demand for biomass.

ndb.generate_scenario_report()

Power generation

Run

from premise import *

import brightway2 as bw

bw.projects.set_current("my_project)

ndb = NewDatabase(

scenarios=[

{"model":"remind", "pathway":"SSP2-Base", "year":2028}

],

source_db="ecoinvent 3.7 cutoff",

source_version="3.7.1",

key='xxxxxxxxxxxxxxxxxxxxxxxxx'

)

ndb.update("electricity")

The energy conversion efficiency of power plant datasets for specific technologies is adjusted to align with the efficiency changes indicated by the IAM scenario. Two approaches are posisble: * application of a scaling factor to the inputs of the dataset relative to the current efficiency * application of a scaling factor to the inputs of the dataset to match the absolute efficiency given by the IAM scenario

The first approach (default) preserves

Combustion-based powerplants

First, premise adjust the efficiency of coal- and lignite-fired power plants on the basis of the excellent work done by Oberschelp et al. (2019), to update some datasets in ecoinvent, which are, for some of them, several decades old. More specifically, the data provides plant-specific efficiency and emissions factors. We average them by country and fuel type to obtain volume-weighted factors. The efficiency of the following datasets is updated:

electricity production, hard coal

electricity production, lignite

heat and power co-generation, hard coal

heat and power co-generation, lignite

The data from Oberschelp et al. (2019) also allows us to update emissions of SO2, NOx, CH4, and PMs.

Second, premise iterates through coal, lignite, natural gas, biogas, and wood-fired power plant datasets in the LCI database to calculate their current efficiency (i.e., the ratio between the primary fuel energy entering the process and the output energy produced, which is often 1 kWh). If the IAM scenario anticipates a change in efficiency for these processes, the inputs of the datasets are scaled up or down by the scaling factor to effectively reflect a change in fuel input per kWh produced.

The origin of this scaling factor is the IAM scenario selected.

To calculate the old and new efficiency of the dataset, it is necessary to know the net calorific content of the fuel. The table below shows the Lower Heating Value for the different fuels used in combustion-based power plants.

name of fuel

LHV [MJ/kg, as received]

hard coal

26.7

lignite

11.2

petroleum coke

31.3

wood pellet

16.2

wood chips

18.9

natural gas

45

gas, natural, in ground

45

refinery gas

50.3

propane

46.46

heavy fuel oil

38.5

oil, crude, in ground

38.5

light fuel oil

42.6

biogas

22.73

biomethane

47.5

waste

14

methane, fossil

47.5

methane, biogenic

47.5

methane, synthetic

47.5

diesel

43

gasoline

42.6

petrol, 5% ethanol

41.7

petrol, synthetic, hydrogen

42.6

petrol, synthetic, coal

42.6

diesel, synthetic, hydrogen

43

diesel, synthetic, coal

43

diesel, synthetic, wood

43

diesel, synthetic, wood, with CCS

43

diesel, synthetic, grass

43

diesel, synthetic, grass, with CCS

43

hydrogen, petroleum

120

hydrogen, electrolysis

120

hydrogen, biomass

120

hydrogen, biomass, with CCS

120

hydrogen, coal

120

hydrogen, from natural gas

120

hydrogen, from natural gas, with CCS

120

hydrogen, biogas

120

hydrogen, biogas, with CCS

120

hydrogen

120

biodiesel, oil

38

biodiesel, oil, with CCS

38

bioethanol, wood

26.5

bioethanol, wood, with CCS

26.5

bioethanol, grass

26.5

bioethanol, grass, with CCS

26.5

bioethanol, grain

26.5

bioethanol, grain, with CCS

26.5

bioethanol, sugar

26.5

bioethanol, sugar, with CCS

26.5

ethanol

26.5

methanol, wood

19.9

methanol, grass

19.9

methanol, wood, with CCS

19.9

methanol, grass, with CCS

19.9

liquified petroleum gas, natural

45.5

liquified petroleum gas, synthetic

45.5

uranium, enriched 3.8%, in fuel element for light water reactor

4199040

nuclear fuel element, for boiling water reactor, uo2 3.8%

4147200

nuclear fuel element, for boiling water reactor, uo2 4.0%

4147200

nuclear fuel element, for pressure water reactor, uo2 3.8%

4579200

nuclear fuel element, for pressure water reactor, uo2 4.0%

4579200

nuclear fuel element, for pressure water reactor, uo2 4.2%

4579200

uranium hexafluoride

709166

enriched uranium, 4.2%

4579200

mox fuel element

4579200

heat, from hard coal

1

heat, from lignite

1

heat, from petroleum coke

1

heat, from wood pellet

1

heat, from natural gas, high pressure

1

heat, from natural gas, low pressure

1

heat, from heavy fuel oil

1

heat, from light fuel oil

1

heat, from biogas

1

heat, from waste

1

heat, from methane, fossil

1

heat, from methane, biogenic

1

heat, from diesel

1

heat, from gasoline

1

heat, from bioethanol

1

heat, from biodiesel

1

heat, from liquified petroleum gas, natural

1

heat, from liquified petroleum gas, synthetic

1

bagasse, from sugarcane

15.4

bagasse, from sweet sorghum

13.8

sweet sorghum stem

4.45

cottonseed

21.97

flax husks

21.5

coconut husk

20

sugar beet pulp

5.11

cleft timber

14.46

rape meal

31.1

molasse, from sugar beet

16.65

sugar beet

4.1

barkey grain

19.49

rye grain

12

sugarcane

5.3

palm date

10.8

whey

1.28

straw

15.5

grass

17

manure, liquid

0.875

manure, solid

3.6

kerosene, from petroleum

43

kerosene, synthetic, from electrolysis, energy allocation

43

kerosene, synthetic, from electrolysis, economic allocation

43

kerosene, synthetic, from coal, energy allocation

43

kerosene, synthetic, from coal, economic allocation

43

kerosene, synthetic, from natural gas, energy allocation

43

kerosene, synthetic, from natural gas, economic allocation

43

kerosene, synthetic, from biomethane, energy allocation

43

kerosene, synthetic, from biomethane, economic allocation

43

kerosene, synthetic, from biomass, energy allocation

43

kerosene, synthetic, from biomass, economic allocation

43

Additionally, the biogenic and fossil CO2 emissions of the datasets are also scaled up or down by the same factor, as they are proportional to the amount of fuel used.

Below is an example of a natural gas power plant with a current (2020) conversion efficiency of 77%. If the IAM scenario indicates a scaling factor of 1.03 in 2030, this suggests that the efficiency increases by 3% relative to the current level. As shown in the table below, this would result in a new efficiency of 79%, where all inputs, as well as CO2 emissions outputs, are re-scaled by 1/1.03 (=0.97).

While non-CO2 emissions (e.g., CO) are reduced because of the reduction in fuel consumption, the emission factor per energy unit remains the same (i.e., gCO/MJ natural gas)). It can be re-scaled using the .update(“emissions”) function, which updates emission factors according to GAINS projections.

electricity production, natura gas, conventional

before

after

unit

electricity production

1

1

kWh

natural gas

0.1040

0.1010

m3

water

0.0200

0.0194

m3

powerplant construction

1.00E-08

9.71E-09

unit

CO2, fossil

0.0059

0.0057

kg

CO, fossil

5.87E-06

5.42E-03

kg

fuel-to-electricity efficiency

77%

79%

%

premise has a couple of rules regarding projected scaling factors:

scaling factors inferior to 1 beyond 2020 are not accepted and are treated as 1.

scaling factors superior to 1 before 2020 are not accepted and are treated as 1.

efficiency can only improve over time.

This is to prevent degrading the performance of a technology in the future, or improving its performance in the past, relative to today.

Note

You can check the efficiencies assumed in your scenarios by generating a scenario summary report, or a report of changes. They are automatically generated after each database export, but you can also generate them manually:

ndb.generate_scenario_report()

ndb.generate_change_report()

Photovoltaics panels

Photovoltaic panels are expected to improve over time. The following module efficiencies are considered for the different types of PV panels:

% module efficiency

micro-Si

single-Si

multi-Si

CIGS

CIS

CdTe

2010

10

15.1

14

11

11

10

2020

11.9

17.9

16.8

14

14

16.8

2050

12.5

26.7

24.4

23.4

23.4

21

The sources for these efficiencies are given in the inventory file LCI_PV:

Given a scenario year, premise iterates through the different PV panel installation datasets to update their efficiency accordingly. To do so, the required surface of panel (in m2) per kW of capacity is adjusted down (or up, if the efficiency is lower than current).

To calculate the current efficiency of a PV installation, premise assumes a solar irradiation of 1000 W/m2. Hence, the current efficiency is calculated as:

current_eff [%] = installation_power [W] / (panel_surface [m2] * 1000 [W/m2])

The scaling factor is calculated as:

scaling_factor = current_eff / new_eff

The required surface of PV panel in the dataset is then adjusted like so:

new_surface = current_surface * (1 / scaling_factor)

For scenario years beyond 2050, 2050 efficiency values are used.

The table below provides such an example where a 450 kWp flat-roof installation sees its current (2020) module efficiency improving from 20% to 26% by 2050. THe are of PV panel (and mounting system) has been multiplied by 1 / (0.26/0.20), all other inputs remaining unchanged.

450kWp flat roof installation

before

after

unit

photovoltaic flat-roof installation, 450 kWp, single-SI, on roof

1

1

unit

inverter production, 500 kW

1.5

1.5

unit

photovoltaic mounting system, …

2300

1731

m2

photovoltaic panel, single-SI

2500

1881

m2

treatment, single-SI PV module

30000

30000

kg

electricity, low voltage

25

25

kWh

module efficiency

20%

26%

%

Markets

premise creates additional datasets that represent the average supply and production pathway for a given commodity for a given scenario, year and region.

Such datasets are called regional markets. Hence, a regional market for high voltage electricity contains the different technologies that supply electricity at high voltage in a given IAM region, in proportion to their respective production volumes.

Regional electricity markets

premise creates high, medium and low-voltage electricity markets for each IAM region. It starts by creating high-voltage markets and define the share of each supplying technology by their respective production volumes in respect to the total volume produced.

High voltage supplying technologies are all technologies besides:

residential (<=3kWp) photovoltaic power (low voltage)

waste incineration co-generating powerplants (medium voltage)

Several datasets can qualify for a given technology, in a given IAM region. To define to which extent a given dataset should be supplying in the market, premise uses the current production volume of the dataset.

For example, if coal-fired powerplants are to supply 25% of the high voltage electricity in the IAM region “Europe”, premise fetches the production volumes of all coal-fired powerplants which ecoinvent location is included in the IAM region “Europe” (e.g., DE, PL, LT, etc.), and allocates to each of those a supply share based on their respective production volume in respect to the total production volume of coal-fired powerplants.

For example, the table below shows the contribution of biomass-fired CHP powerplants in the regional high voltage electricity market for IMAGE’s “WEU” region (Western Europe). The biomass CHP technology represents 2.46% of the supply mix. Biomass CHP datasets included in the region “WEU” are given a supply share corresponding to their respective current production volumes.

energy type

Supplier name

Supplier location

Contribution within energy type

Final contribution

Biomass CHP

heat and power co-generation, wood chips

FR

3.80%

0.09%

Biomass CHP

heat and power co-generation, wood chips

AT

2.87%

0.07%

Biomass CHP

heat and power co-generation, wood chips

NO

0.06%

0.00%

Biomass CHP

heat and power co-generation, wood chips

FI

7.65%

0.19%

Biomass CHP

heat and power co-generation, wood chips

SE

9.04%

0.22%

Biomass CHP

heat and power co-generation, wood chips

IT

8.27%

0.20%

Biomass CHP

heat and power co-generation, wood chips

BE

4.59%

0.11%

Biomass CHP

heat and power co-generation, wood chips

DE

12.53%

0.31%

Biomass CHP

heat and power co-generation, wood chips

LU

0.05%

0.00%

Biomass CHP

heat and power co-generation, wood chips

DK

6.60%

0.16%

Biomass CHP

heat and power co-generation, wood chips

GR

0.01%

0.00%

Biomass CHP

heat and power co-generation, wood chips

CH

1.81%

0.04%

Biomass CHP

heat and power co-generation, wood chips

ES

5.10%

0.13%

Biomass CHP

heat and power co-generation, wood chips

PT

1.34%

0.03%

Biomass CHP

heat and power co-generation, wood chips

IE

0.77%

0.02%

Biomass CHP

heat and power co-generation, wood chips

NL

2.32%

0.06%

Biomass CHP

heat and power co-generation, wood chips

GB

33.18%

0.81%

_

_

Sum

100.00%

2.46%

Transformation losses are added to the high-voltage market datasets. Transformation losses are the result of weighting country-specific high voltage losses (provided by ecoinvent) of countries included in the IAM region with their respective current production volumes (also provided by ecoinvent). This is not ideal as it supposes that future country-specific production volumes will remain the same in respect to one another.

Storage

If the IAM scenario requires the use of storage, premise adds a storage dataset to the high voltage market. premise can add two types of storage:

storage via a large-scale flow battery (electricity supply, high voltage, from vanadium-redox flow battery system)

storage via the conversion of electricity to hydrogen and subsequent use in a gas turbine (electricity production, from hydrogen-fired one gigawatt gas turbine)

The electricity storage via battery incurs a 33% loss. It is operated by a 8.3 MWh vanadium redox-based flow battery, with a lifetime of 20 years or 8176 cycle-lifes (i.e., 49,000 MWh).

The storage of electricity via hydrogen is done in two steps: first, the electricity is converted to hydrogen via a 1MW PEM electrolyser, with an efficiency of 62%. The hydrogen is then stored in a geological cavity and used in a gas turbine, with an efficiency of 51%. Accounting for leakages and losses, the overall efficiency of the process is about 37% (i.e., 2.7 kWh necessary to deliver 1 kWh to the grid).

The efficiency of the H2-fed gas turbine is based on the parameters of Ozawa et al. (2019).

The workflow is not too different from that of high voltage markets. There are however only two possible providers of electricity in medium voltage markets: the high voltage market, as well as waste incineration powerplants.

High-to-medium transformation losses are added as an input of the medium voltage market to itself. Distribution losses are modelled the same way as for high voltage markets and are added to the input from high voltage market.

Low voltage regional markets receive an input from the medium voltage market, as well as from residential photovoltaic power.

Medium-to-low transformation losses are added as an input from the low voltage market to itself. Distribution losses are modelled the same way as for high and medium voltage markets, and are added to the input from the medium voltage market.

The table below shows the example of a low voltage market for the IAM IMAGE regional “WEU”.

supplier

amount

unit

location

description

market group for electricity, medium voltage

1.023880481

kilowatt hour

WEU

input from medium voltage + distribution losses

market group for electricity, low voltage

0.025538286

kilowatt hour

WEU

transformation losses (2.55%)

electricity production, photovoltaic, residential

0.00035691

kilowatt hour

DE

electricity production, photovoltaic, residential

0.000143875

kilowatt hour

IT

electricity production, photovoltaic, residential

9.38E-05

kilowatt hour

ES

electricity production, photovoltaic, residential

9.03E-05

kilowatt hour

GB

electricity production, photovoltaic, residential

7.82E-05

kilowatt hour

FR

electricity production, photovoltaic, residential

6.80E-05

kilowatt hour

NL

electricity production, photovoltaic, residential

3.76E-05

kilowatt hour

BE

electricity production, photovoltaic, residential

2.16E-05

kilowatt hour

GR

electricity production, photovoltaic, residential

2.08E-05

kilowatt hour

CH

electricity production, photovoltaic, residential

1.48E-05

kilowatt hour

AT

electricity production, photovoltaic, residential

9.44E-06

kilowatt hour

SE

electricity production, photovoltaic, residential

8.66E-06

kilowatt hour

DK

electricity production, photovoltaic, residential

6.83E-06

kilowatt hour

PT

electricity production, photovoltaic, residential

2.60E-06

kilowatt hour

FI

electricity production, photovoltaic, residential

1.30E-06

kilowatt hour

LU

electricity production, photovoltaic, residential

1.01E-06

kilowatt hour

NO

electricity production, photovoltaic, residential

2.40E-07

kilowatt hour

IE

distribution network construction, electricity, low voltage

8.74E-08

kilometer

RoW

market for sulfur hexafluoride, liquid

2.99E-09

kilogram

RoW

sulfur hexafluoride

2.99E-09

kilogram

transformer emissions

Note

You can check the electricity supply mixes assumed in your scenarios by generating a scenario summary report.

ndb.generate_scenario_report()

Long-term regional electricity markets

Long-term (i.e., 20, 40 and 60 years) regional markets are created for modelling the lifetime-weighted burden associated to electricity supply for systems that have a long lifetime (e.g., battery electric vehicles, buildings).

These long-term markets contain a period-weighted electricity supply mix. For example, if the scenario year is 2030 and the period considered is 20 years, the supply mix represents the supply mixes between 2030 and 2050, with an equal weight given to each year.

The rest of the modelling is similar to that of regular regional electricity markets described above.

Market datasets originally present in the ecoinvent LCI database are cleared from any inputs. Instead, an input from the newly created regional market is added, depending on the location of the dataset.

The table below shows the example of the low voltage electricity market for Great Britain, which now only includes an input from the “WEU” regional market, which “includes” it in terms of geography.

Output

_

_

_

producer

amount

unit

location

market for electricity, low voltage

1.00E+00

kilowatt hour

GB

Input

_

_

_

supplier

amount

unit

location

market group for electricity, low voltage

1.00E+00

kilowatt hour

WEU

Once the new markets are created, premise re-links all electricity-consuming activities to the new regional markets. The regional market it re-links to depends on the location of the consumer.

Cement production

The modelling of future improvements in the cement sector is relatively simple at the moment, and does not involve the emergence of new technologies (e.g., electric kilns).

Run

from premise import *

import brightway2 as bw

bw.projects.set_current("my_project)

ndb = NewDatabase(

scenarios=[

{"model":"remind", "pathway":"SSP2-Base", "year":2028}

],

source_db="ecoinvent 3.7 cutoff",

source_version="3.7.1",

key='xxxxxxxxxxxxxxxxxxxxxxxxx'

)

ndb.update("cement")

premise duplicates clinker production datasets in ecoinvent (called “clinker production”) so as to create a proxy dataset for each IAM region. The location of the proxy datasets used for a given IAM region is a location included in the IAM region. If no valid dataset is found, premise resorts to using a rest-of-the-world (RoW) dataset to represent the IAM region.

premise changes the location of these duplicated datasets and fill in different fields, such as that of production volume.

premise then adjusts the thermal efficiency of the process. It does so by calculating the technology-weighted energy requirements per ton of clinker. Based on GNR/IEA roadmap data, premise uses:

- the share of kiln technology for a given region today (2020):

wet,

dry,

dry with pre-heater,

and dry with pre-heater and pre-calciner

the energy requirement for each of these technologies today (2020).

Once the energy required per ton clinker today (2020) is known, it is multiplied by a scaling factor that represents a change in efficiency between today and the scenario year.

Note

You can check the efficiency gains assumed relative to 2020 in your scenarios by generating a scenario summary report.

ndb.generate_scenario_report()

Note

premise enforces a lower limit on the fuel consumption per ton of clinker. This limit is set to 2.8 GJ/t clinker and corresponds to the minimum theoretical fuel consumption with an moisture content of the raw materials, as considered in the 2018 IEA cement roadmap report. Hence, regardless of the scaling factor, the fuel consumption per ton of clinker will never be less than 2.8 GJ/t.

Once the new energy input is determined, premise scales down the fuel, and the fossil and biogenic CO2 emissions accordingly, based on the Lower Heating Value and CO2 emission factors for these fuels.

Note that the change in CO2 emissions only concerns the share that originates from the combustion of fuels. It does not concern the calcination emissions due to the production of calcium oxide (CaO) from calcium carbonate (CaCO3), which is set at a fix emission rate of 525 kg CO2/t clinker.

If the IAM scenario indicates that a share of the CO2 emissions for the cement sector in a given region and year is sequestered and stored, premise adds CCS to the corresponding clinker production dataset.

The CCS dataset used to that effect is from Meunier et al., 2020. The dataset described the capture of CO2 from a cement plant. To that dataset, premise adds another dataset that models the storage of the CO2 underground, from Volkart et al, 2013.

Besides electricity, the CCS process requires heat, water and others inputs to regenerate the amine-based sorbent. We use two data points to approximate the heat requirement: 3.66 MJ/kg CO2 captured in 2020, and 2.6 MJ/kg in 2050. The first number is from Meunier et al., 2020, while the second number is described as the best-performing pilot project today, according to the 2022 review of pilot projects by the Global CCS Institute. It is further assumed that the heat requirement is fulfilled to an extent of 15% by the recovery of excess heat, as mentioned in the 2018 IEA cement roadmap report.

Note

You can check the the carbon capture rate for cement production assumed in your scenarios by generating a scenario summary report.

ndb.generate_scenario_report()

Run

from premise import *

import brightway2 as bw

bw.projects.set_current("my_project)

ndb = NewDatabase(

scenarios=[

{"model":"remind", "pathway":"SSP2-Base", "year":2028}

],

source_db="ecoinvent 3.7 cutoff",

source_version="3.7.1",

key='xxxxxxxxxxxxxxxxxxxxxxxxx'

)

ndb.update("cement")

When clinker production datasets are created for each IAM region, premise duplicates cement production datasets for each IAM region as well. These cement production datasets link the newly created clinker production dataset, corresponding to their IAM region.

premise used to modify the composition of cement markets to reflect a lower clinker content over time, based on external projections. This is no longer performed, as it is not an assumption stemming from the IAM model, but rather a projection of the cement industry.

Market datasets originally present in the ecoinvent LCI database are cleared from any inputs. Instead, an input from the newly created regional market is added, depending on the location of the dataset.

The table below shows the example of the clinker market for South Africa, which now only includes an input from the “SAF” regional market, which “includes” it in terms of geography.

Output

_

_

_

producer

amount

unit

location

market for clinker

1.00E+00

kilogram

ZA

Input

_

_

_

supplier

amount

unit

location

market for clinker

1.00E+00

kilogram

*SAF

Once cement production and market datasets are created, premise re-links cement-consuming activities to the new regional markets for cement. The regional market it re-links to depends on the location of the consumer.

Steel production

Run

from premise import *

import brightway2 as bw

bw.projects.set_current("my_project)

ndb = NewDatabase(

scenarios=[

{"model":"remind", "pathway":"SSP2-Base", "year":2028}

],

source_db="ecoinvent 3.7 cutoff",

source_version="3.7.1",

key='xxxxxxxxxxxxxxxxxxxxxxxxx'

)

ndb.update("steel")"

The modelling of future improvements in the steel sector is relatively simple at the moment, and does not involve the emergence of new technologies (e.g., hydrogen-based DRI, electro-winning).

premise duplicates steel production datasets in ecoinvent for the production of primary and secondary steel (called respectively “steel production, converter” and “steel production, electric”) so as to create a proxy dataset for each IAM region.

The location of the proxy datasets used for a given IAM region is a location included in the IAM region. If no valid dataset is found, premise resorts to using a rest-of-the-world (RoW) dataset to represent the IAM region.

premise changes the location of these duplicated datasets and fill in different fields, such as that of production volume.

Regarding primary steel production (using BO-BOF), premise adjusts the inputs of fuels found in:

the pig iron production datasets,

the steel production datasets,

assuming an integrated steel mill unit, by multiplying these fuel inputs by a scaling factor provided by the IAM scenario.

Typical fuel inputs for these process are natural gas, coal, coal-based coke. Emissions of (fossil) CO2 are scaled accordingly.

Regarding the production of secondary steel (using EAF), premise adjusts the input of electricity based on the scaling factor provided by the IAM scenario.

Note

You can check the efficiency gains assumed relative to 2020 for steel production in your scenarios by generating a scenario summary report.

ndb.generate_scenario_report()

Warning

If your system of interest relies heavily on the provision of steel, you should probably consider modelling steel production based on primary data. ecoinvent datasets for steel production rely on a few data points, which are then further process transformed by premise. Therefore, there is a large modelling uncertainty.

If the IAM scenario indicates that a share of the CO2 emissions from the steel sector in a given region and year is sequestered and stored, premise adds a corresponding input from a CCS dataset. The datatset used to that effect is from Meunier et al., 2020. The dataset described the capture of CO2 from a cement plant, not a steel mill, but it is assumed to be an acceptable approximation since the CO2 concentration in the flue gases should not be significantly different.

To that dataset, premise adds another dataset that models the storage of the CO2 underground, from Volkart et al, 2013.

Besides electricity, the CCS process requires heat, water and others inputs to regenerate the amine-based sorbent. We use two data points to approximate the heat requirement: 3.66 MJ/kg CO2 captured in 2020, and 2.6 MJ/kg in 2050. The first number is from Meunier et al., 2020, while the second number is described as the best-performing pilot project today, according to the 2022 review of pilot projects by the Global CCS Institute. It is further assumed that the heat requirement is fulfilled to an extent of 15% by the recovery of excess heat, as mentioned in the 2018 IEA cement roadmap report, which is assumed to be also valid in the case of a steel mill.

premise create a dataset “market for steel, low-alloyed” for each IAM region. Within each dataset, the supply shares of primary and secondary steel are adjusted to reflect the projections from the IAM scenario, for a given region and year, based on the variables below.

name in premise

name in REMIND

name in IMAGE

name in LCI database

steel - primary

Production|Industry|Steel|Primary

Production|Steel|Primary

steel production, converter

steel - secondary

Production|Industry|Steel|Secondary

Production|Steel|Secondary

steel production, electric

The table below shows an example of the market for India, where 66% of the steel comes from an oxygen converter process (primary steel), while 34% comes from an electric arc furnace process (secondary steel).

Output

_

_

_

producer

amount

unit

location

market for steel, low-alloyed

1

kilogram

IND

Input

supplier

amount

unit

location

market group for transport, freight, inland waterways, barge

0.5

ton kilometer

GLO

market group for transport, freight train

0.35

ton kilometer

GLO

market for transport, freight, sea, bulk carrier for dry goods

0.38

ton kilometer

GLO

transport, freight, lorry, unspecified, regional delivery

0.12

ton kilometer

IND

steel production, converter, low-alloyed

0.66

kilogram

IND

steel production, electric, low-alloyed

0.34

kilogram

IND

Market datasets originally present in the ecoinvent LCI database are cleared from any inputs. Instead, an input from the newly created regional market is added, depending on the location of the dataset.

The table below shows the example of the clinker market for South Africa, which now only includes an input from the “SAF” regional market, which “includes” it in terms of geography.

Output

_

_

_

producer

amount

unit

location

market for clinker

1.00E+00

kilogram

ZA

Input

_

_

_

supplier

amount

unit

location

market for clinker

1.00E+00

kilogram

SAF

Once steel production and market datasets are created, premise re-links steel-consuming activities to the new regional markets for steel. The regional market it re-links to depends on the location of the consumer.

Transport

Run

from premise import *

import brightway2 as bw

bw.projects.set_current("my_project)

ndb = NewDatabase(

scenarios=[

{"model":"remind", "pathway":"SSP2-Base", "year":2028}

],

source_db="ecoinvent 3.7 cutoff",

source_version="3.7.1",

key='xxxxxxxxxxxxxxxxxxxxxxxxx'

)

ndb.update("two_wheelers")

ndb.update("cars")

ndb.update("trucks")

ndb.update("buses")

premise imports inventories for transport activity operated by:

two-wheelers

passenger cars

medium and heavy duty trucks

buses

These inventories are available for the construction year of 2000 to 2050, by steps of 5 years, but premise only imports vehicles with a construction year inferior or equal to the scenario year (vehicle from 2050 will not be imported in a database for the scenario year of 2030, but vehicles from 2020 will, as they are necessary to build the fleet average vehicles).

The following size classes of medium and heavy duty trucks are imported:

3.5t

7.5t

18t

26t

40t

These weights refer to the vehicle gross mass (the maximum weight the vehicle is allowed to reach, fully loaded).

Each truck is available for a variety of powertrain types:

fuel cell electric

battery electric

diesel hybrid

plugin diesel hybrid

diesel

compressed gas

but also for different driving cycles, to which a range autonomy of the vehicle is associated:

urban delivery (required range autonomy of 150 km)

regional delivery (required range autonomy of 400 km)

long haul (required range autonomy of 800 km)

Those are driving cycles developed for the software VECTO, which have become standard in measuring the CO2 emissions of trucks.

The truck vehicle model is from Sacchi et al, 2021.

Note

Not all powertrain types are available for regional and long haul driving cycles. This is specifically the case for battery electric trucks, for which the mass and size prevent them from completing the cycle, or surpasses the vehicle gross weight.

Warning

A consequence of replacing original truck datasets with those provided by premise may be a steep increase in CO2-eq. emissions, especially if the urban driving cycle is chosen. Overall, considering and size classes, diesel truck datasets from ecoinvent have lower fuel consumption and exhaust emissions.

Fleet average trucks

REMIND and IMAGE provide fleet composition data, per scenario, region and year.

The fleet data is expressed in “vehicle-kilometer” performed by each type of vehicle, in a given region and year.

premise uses the following loads to translate the transport demand from “vehicle-kilometers” to “ton-kilometers”, derived from TRACCS:

load [tons]

urban delivery

regional delivery

long haul

3.5t

0.26

0.26

0.8

7.5t

0.52

0.52

1.6

18t

1.35

1.35

4.1

26t

2.05

2.05

6.2

32t

6.1

6.1

9.1

40t

6.1

6.1

9.1

Note

Loads from the TRACCS survey data are representative for EU-28 conditions. premise applies these loads to all IAM regions. Hence, there might be some inconsistency at this level. Also, these loads are much lower than those assumed in original ecoinvent truck datasets.

premise uses the fleet data to produce fleet average trucks for each IAM region, and more specifically:

a fleet average truck, all powertrains and size classes considered

a fleet average truck, all powertrains considered, for a given size class

They appear in the LCI database as the following:

truck transport dataset name

description

transport, freight, lorry, 3.5t gross weight, unspecified powertrain, long haul

fleet average, for 3.5t size class, long haul cycle

transport, freight, lorry, 3.5t gross weight, unspecified powertrain, regional delivery

fleet average, for 3.5t size class, regional delivery cycle

transport, freight, lorry, 3.5t gross weight, unspecified powertrain, urban delivery

fleet average, for 3.5t size class, urban delivery cycle

transport, freight, lorry, 7.5t gross weight, unspecified powertrain, long haul

fleet average, for 7.5t size class, long haul cycle

transport, freight, lorry, 7.5t gross weight, unspecified powertrain, regional delivery

fleet average, for 7.5t size class, regional delivery cycle

transport, freight, lorry, 7.5t gross weight, unspecified powertrain, urban delivery

fleet average, for 7.5t size class, urban delivery cycle

transport, freight, lorry, 18t gross weight, unspecified powertrain, long haul

fleet average, for 18t size class, long haul cycle

transport, freight, lorry, 18t gross weight, unspecified powertrain, regional delivery

fleet average, for 18t size class, regional delivery cycle

transport, freight, lorry, 18t gross weight, unspecified powertrain, urban delivery

fleet average, for 18t size class, urban delivery cycle

transport, freight, lorry, 26t gross weight, unspecified powertrain, long haul

fleet average, for 26t size class, long haul cycle

transport, freight, lorry, 26t gross weight, unspecified powertrain, regional delivery

fleet average, for 26t size class, regional delivery cycle

transport, freight, lorry, 26t gross weight, unspecified powertrain, urban delivery

fleet average, for 26t size class, urban delivery cycle

transport, freight, lorry, 40t gross weight, unspecified powertrain, long haul

fleet average, for 26t size class, long haul cycle

transport, freight, lorry, 40t gross weight, unspecified powertrain, regional delivery

fleet average, for 26t size class, regional delivery cycle

transport, freight, lorry, 40t gross weight, unspecified powertrain, urban delivery

fleet average, for 26t size class, urban delivery cycle

transport, freight, lorry, unspecified, long haul

fleet average, all powertrain types, all size classes

transport, freight, lorry, unspecified, regional delivery

fleet average, all powertrain types, all size classes

transport, freight, lorry, unspecified, urban delivery

fleet average, all powertrain types, all size classes

Relinking

Regarding trucks, premise re-links truck transport-consuming activities to the newly created fleet average truck datasets.

The following table shows the correspondence between the original truck transport datasets and the new ones replacing them:

Original dataset

Replaced by (REMIND)

Replaced by (IMAGE)

transport, freight, lorry, unspecified

transport, freight, lorry, unspecified

transport, freight, lorry, unspecified

transport, freight, lorry 16-32 metric ton

transport, freight, lorry, 26t gross weight, unspecified powertrain

transport, freight, lorry, 26t gross weight, unspecified powertrain

transport, freight, lorry 28 metric ton, fatty acid methyl ester 100%

transport, freight, lorry, 26t gross weight, unspecified powertrain

transport, freight, lorry, 26t gross weight, unspecified powertrain

transport, freight, lorry 3.5-7.5 metric ton

transport, freight, lorry, 3.5t gross weight, unspecified powertrain

transport, freight, lorry, 26t gross weight, unspecified powertrain

transport, freight, lorry 7.5-16 metric ton

transport, freight, lorry, 7.5t gross weight, unspecified powertrain

transport, freight, lorry, 26t gross weight, unspecified powertrain

transport, freight, lorry >32 metric ton

transport, freight, lorry, 40t gross weight, unspecified powertrain

transport, freight, lorry, 40t gross weight, unspecified powertrain

transport, freight, lorry with reefer, cooling

transport, freight, lorry, unspecified

transport, freight, lorry, unspecified

transport, freight, lorry with reefer, freezing

transport, freight, lorry, unspecified

transport, freight, lorry, unspecified

transport, freight, lorry with refrigeration machine, 3.5-7.5 ton

transport, freight, lorry, 3.5t gross weight, unspecified powertrain

transport, freight, lorry, 26t gross weight, unspecified powertrain

transport, freight, lorry with refrigeration machine, 7.5-16 ton

transport, freight, lorry, 7.5t gross weight, unspecified powertrain

transport, freight, lorry, 26t gross weight, unspecified powertrain

transport, freight, lorry with refrigeration machine, cooling

transport, freight, lorry, unspecified

transport, freight, lorry, unspecified

transport, freight, lorry with refrigeration machine, freezing

transport, freight, lorry, unspecified

transport, freight, lorry, unspecified

Note that IMAGE fleet data only uses 26t and 40t trucks.

Additionally, premise iterates through each truck transport-consuming activities to calculate the driving distance required. When the reference unit of the dataset is 1 kilogram, the distance driven by truck can easily be inferred. Indeed, for example, 0.56 tkm of truck transport for 1 kg of flour indicates that the flour has been transported over 560 km.

On this basis, premise chooses one of the following driving cycles:

regional delivery, if the distance is inferior or equal to 450 km

long haul, if the distance is superior to 450 km

Hence, in the following dataset for “market for steel, low-alloyed” for the IAM region of India, premise chose the regional delivery driving cycle since the kilogram of steel has been transported on average over 120 km by truck. The truck used to transport that kilogram of steel is a fleet average vehicle built upon the REMIND fleet data for the region of India.

Output

_

_

_

producer

amount

unit

location

market for steel, low-alloyed

1

kilogram

IND

Input

supplier

amount

unit

location

market group for transport, freight, inland waterways, barge

0.5

ton kilometer

GLO

market group for transport, freight train

0.35

ton kilometer

GLO

market for transport, freight, sea, bulk carrier for dry goods

0.38

ton kilometer

GLO

transport, freight, lorry, unspecified, regional delivery

0.12

ton kilometer

IND

steel production, converter, low-alloyed

0.66

kilogram

IND

steel production, electric, low-alloyed

0.34

kilogram

IND

Direct Air Capture

Run

from premise import *

import brightway2 as bw

bw.projects.set_current("my_project)

ndb = NewDatabase(

scenarios=[

{"model":"remind", "pathway":"SSP2-Base", "year":2028}

],

source_db="ecoinvent 3.7 cutoff",

source_version="3.7.1",

key='xxxxxxxxxxxxxxxxxxxxxxxxx'

)

ndb.update("dac")

premise creates different region-specific Direct Air Capture (DAC) datasets, based on the inventories from Qiu et al., 2022.

If provided by the IAM scenario, premise scales the inputs of electricity and heat of the DAC datasets to reflect changes in efficiency.

Fuels

Run

from premise import *

import brightway2 as bw

bw.projects.set_current("my_project)

ndb = NewDatabase(

scenarios=[

{"model":"remind", "pathway":"SSP2-Base", "year":2028}

],

source_db="ecoinvent 3.7 cutoff",

source_version="3.7.1",

key='xxxxxxxxxxxxxxxxxxxxxxxxx'

)

ndb.update("fuels")

premise create different region-specific fuel supply chains and fuel markets, based on data from the IAM scenario.

The biomass-to-fuel efficiency ratio of bioethanol and biodiesel production datasets is adjusted according to the IAM scenario projections.

Inputs to the biofuel production datasets are multiplied by a scaling factor that represents the change in efficiency relative to today (2020).

Several pathways for hydrogen production are modeled in premise:

electrolysis

steam methane reforming of natural gas

steam methane reforming of biomethane

gasification of coal

gasification of woody biomass

The last four pathways are modeled with and without CCS.

Inventories for these pathways are available under:

premise/data/additional_inventories/lci-hydrogen-electrolysis.xlsx

premise/data/additional_inventories/lci-smr-atr-natgas.xlsx

premise/data/additional_inventories/lci-smr-atr-biogas.xlsx

premise/data/additional_inventories/lci-hydrogen-coal-gasification.xlsx

premise/data/additional_inventories/lci-hydrogen-wood-gasification.xlsx

In case the IAM variable that relates to a given hydrogen pathway’s efficiency is not available, the process’ efficiency is not modified, with the exception of electrolysis, which is modified regardless.

A scaling factor is calculated for each pathway, which is the ratio between the IAM variable value for the year in question and the current efficiency value (i.e., in 2020). premise uses this scaling factor to adjust the amount of feedstock input to produce 1 kg of hydrogen (e.g., m3 of natural gas per kg hydrogen).

If the IAM variable that relates to the efficiency of the electrolysis hydrogen process is not available, premise adjusts the amount of electricity needed to produce 1 kg of hydrogen by electrolysis, on the basis of the following requirements, which are sourced from Bauer et al, 2022:

kWh/kg H2, 25 bar

2010

2020

2050

electricity

58

55

44

When building a database using IMAGE, land use and land use change emissions are available. Upon the import of crops farming datasets, premise adjusts the land occupation as well as CO2 emissions associated to land use and land use change, respectively.

Output

_

_

_

producer

amount

unit

location

Farming and supply of corn

1

kilogram

CEU

Input

supplier

amount

unit

location

market for diesel, burned in agricultural machinery

0.142

megajoule

GLO

petrol, unleaded, burned in machinery

0.042

megajoule

GLO

market for natural gas, burned in gas motor, for storage

0.091

megajoule

GLO

market group for electricity, low voltage

0.004

kilowatt hour

CEU

Energy, gross calorific value, in biomass

15.910

megajoule

_

Occupation, annual crop

1.584

square meter-year

_

Carbon dioxide, in air

1.476

kilogram

_

Carbon dioxide, from soil or biomass stock

1.140

kilogram

_

The land use value is given from the IAM scenario in Ha/GJ of primary crop energy. Hence, the land occupation per kg of crop farmed is calculated as:

land_use = land_use [Ha/GJ] * 10000 [m2/Ha] / 1000 [MJ/GJ] * LHV [MJ/kg]

Regarding land use change CO2 emissions, the principle is similar. The variable is expressed in kg CO2/GJ of primary crop energy. Hence, the land use change CO2 emissions per kg of crop farmed are calculated as:

land_use_co2 = land_use_co2 [kg CO2/GJ] / 1000 [MJ/GJ] * LHV [MJ/kg]

premise builds several supply chains for synthetic fuels, for each IAM region. THe reason for this is that synthetic fuels can be produced from a variety of hydrogen and CO2 sources. Additionally, hydrogen can be supplied by different means of transport, and in different states.

premise starts by building different supply chains for hydrogen by varying:

the transport mode: truck, hydrogen pipeline, re-assigned CNG pipeline, ship,

the distance: 500 km, 2000 km

the state of the hydrogen: gaseous, liquid, liquid organic compound,

the hydrogen production route: electrolysis, SMR, biomass gasifier (coal, woody biomass)

Hence, for each IAM region, the following supply chains for hydrogen are built:

hydrogen supply, from electrolysis, by ship, as liquid, over 2000 km

hydrogen supply, from gasification of biomass by heatpipe reformer, by H2 pipeline, as gaseous, over 500 km

hydrogen supply, from ATR of from natural gas, by truck, as gaseous, over 500 km

hydrogen supply, from gasification of biomass by heatpipe reformer, by truck, as liquid organic compound, over 500 km

hydrogen supply, from SMR of from natural gas, with CCS, by truck, as liquid organic compound, over 500 km

hydrogen supply, from SMR of from natural gas, with CCS, by ship, as liquid, over 2000 km

hydrogen supply, from coal gasification, by CNG pipeline, as gaseous, over 500 km

hydrogen supply, from SMR of from natural gas, by ship, as liquid, over 2000 km

hydrogen supply, from coal gasification, by truck, as liquid, over 500 km

hydrogen supply, from gasification of biomass by heatpipe reformer, by truck, as liquid, over 500 km

hydrogen supply, from ATR of from natural gas, with CCS, by truck, as liquid organic compound, over 500 km

hydrogen supply, from SMR of from natural gas, with CCS, by truck, as liquid, over 500 km

hydrogen supply, from electrolysis, by truck, as liquid organic compound, over 500 km

hydrogen supply, from gasification of biomass, by truck, as liquid organic compound, over 500 km

hydrogen supply, from SMR of from natural gas, with CCS, by truck, as gaseous, over 500 km

hydrogen supply, from SMR of biogas, with CCS, by CNG pipeline, as gaseous, over 500 km

hydrogen supply, from SMR of from natural gas, by truck, as gaseous, over 500 km

hydrogen supply, from SMR of from natural gas, by H2 pipeline, as gaseous, over 500 km

hydrogen supply, from gasification of biomass, with CCS, by truck, as liquid organic compound, over 500 km

hydrogen supply, from gasification of biomass, by ship, as liquid, over 2000 km

Each supply route is associated with specific losses. Losses for the transport of H2 by truck and hydrogen pipelines, and losses at the regional storage storage (salt cavern) are from Wulf et al, 2018. Boil-off loss values during shipping are from Hank et al, 2020. Losses when transporting H2 via re-assigned CNG pipelines are from Cerniauskas et al, 2020. Losses along the pipeline are from Schori et al, 2012., but to be considered conservative, as those are initially for natural gas (and hydrogen has a higher potential for leaking).

_

_

truck

ship

H2 pipeline

CNG pipeline

reference flow

gaseous

compression

0.5%

0.5%

0.5%

per kg H2

_

storage buffer

2.3%

2.3%

per kg H2

_

storage leak

1.0%

1.0%

per kg H2

_

pipeline leak

0.004%

0.004%

per kg H2, per km

_

purification

7.0%

per kg H2

liquid

liquefaction

1.3%

1.3%

per kg H2

_

vaporization

2.0%

2.0%

per kg H2

_

boil-off

0.2%

0.2%

per kg H2, per day

liquid organic compound

hydrogenation

0.5%

per kg H2

Losses are cumulative along the supply chain and range anywhere between 5 and 20%. The table below shows the example of 1 kg of hydrogen transport via re-assigned CNG pipelines, as a gas, over 500 km. A total of 0.13 kg of hydrogen is lost along the supply chain (13% loss):

Output

_

_

_

producer

amount

unit

location

hydrogen supply, from electrolysis, by CNG pipeline, as gaseous, over 500 km

1

kilogram

OCE

Input

supplier

amount

unit

location

hydrogen production, gaseous, 25 bar, from electrolysis

1.133

kilogram

OCE

market group for electricity, low voltage

3.091

kilowatt hour

OCE

market group for electricity, low voltage

0.516

kilowatt hour

OCE

hydrogen embrittlement inhibition

1

kilogram

OCE

geological hydrogen storage

1

kilogram

OCE

Hydrogen refuelling station

1.14E-07

unit

OCE

distribution pipeline for hydrogen, reassigned CNG pipeline

1.56E-08

kilometer

RER

transmission pipeline for hydrogen, reassigned CNG pipeline

1.56E-08

kilometer

RER

7% during the purification of hydrogen: when using CNG pipelines, the hydrogen has to be mixed with another gas to prevent the embrittlement of the pipelines. The separation process at the other end leads to significant losses

2% lost along the 500 km of pipeline

3% at the regional storage (salt cavern)

Also, in this same case, electricity is used:

1.9 kWh to compress the H2 from 25 bar to 100 bar to inject it into the pipeline

1.2 kWh to recompress the H2 along the pipeline every 250 km

0.34 kWh for injecting and pumping H2 into a salt cavern

2.46 kWh to blend the H2 with oxygen on one end, and purify on the other

0.5 kWh to pre-cool the H2 at the fuelling station (necessary if used in fuel cells, for example)

premise builds markets for the following fuels:

market for petrol, unleaded

market for petrol, low-sulfur

market for diesel, low-sulfur

market for diesel

market for natural gas, high pressure

market for hydrogen, gaseous

based on the IAM scenario data regarding the composition of liquid and gaseous secondary energy carriers:

Warning

Some fuel types are not properly represented in the LCI database. Available inventories for biomass-based methanol production do not differentiate between wood and grass as the feedstock.

Note

Modelling choice: premise builds several potential supply chains for hydrogen. Because the logistics to supply hydrogen in the future is not known or indicated by the IAM, the choice is made to supply it by truck over 500 km, in a gaseous state.

Because not all competing fuels of a same type have similar calorific values, some adjustments are made. The table below shows the example of the market for gasoline, for the IMAGE region of Western Europe in 2050. The sum of fuel inputs is superior to 1 (i.e., 1.4 kg). This is because the market dataset as “1 kg” as reference unit, and methanol and bioethanol have low calorific values comparatively to petrol (i.e., 19.9 and 26.5 MJ/kg respectively, vs. 42.6 MJ/kg for gasoline). Hence, their inputs are scaled up to reach an average calorific value of 42.6 MJ/kg of fuel supplied by the market.

This is necessary as gasoline-consuming activities in the lCI database are modelled with the calorific value of conventional gasoline.

Output

_

_

_

producer

amount

unit

location

market for petrol, low-sulfur

1

kilogram

WEU

Input

supplier

amount

unit

location

petrol production, low-sulfur

0.550

kilogram

CH

market for methanol, from biomass

0.169

kilogram

CH

market for methanol, from biomass

0.148

kilogram

CH

market for methanol, from biomass

0.122

kilogram

CH

market for methanol, from biomass

0.122

kilogram

CH

Ethanol production, via fermentation, from switchgrass

0.060

kilogram

WEU

Ethanol production, via fermentation, from switchgrass, with CCS

0.053

kilogram

WEU

Ethanol production, via fermentation, from sugarbeet

0.051

kilogram

WEU

Ethanol production, via fermentation, from sugarbeet, with CCS

0.051

kilogram

WEU

Ethanol production, via fermentation, from poplar, with CCS

0.041

kilogram

WEU

Ethanol production, via fermentation, from poplar

0.041

kilogram

WEU

Run

from premise import *

import brightway2 as bw

bw.projects.set_current("my_project)

ndb = NewDatabase(

scenarios=[

{"model":"remind", "pathway":"SSP2-Base", "year":2028}

],

source_db="ecoinvent 3.7 cutoff",

source_version="3.7.1",

key='xxxxxxxxxxxxxxxxxxxxxxxxx'

)

ndb.update("heat")

Datasets that supply heat and steam via the combustion of natural gas and diesel are regionalized (made available for each region of the IAM model) and relinked to regional fuel markets. If the fuel market contains a share of non-fossil fuels, the CO2 emissions of the heat and steam production are split between fossil and non-fossil emissions. Once regionalized, the heat and steam production datasets relink to activities that require heat within the same region.

Here is a list of the heat and steam production datasets that are regionalized:

diesel, burned in …

steam production, as energy carrier, in chemical industry

heat production, natural gas, …

heat and power co-generation, natural gas, …

heat production, light fuel oil, …

heat production, softwood chips from forest, …

heat production, hardwood chips from forest, …

These datasets are relinked to the corresponding regionalized fuel market only if .update(“fuels”) has been run. Also, heat production datasets that use biomass as fuel input (e.g., softwood and hardwood chips) relink to the dataset market for biomass, used as fuel if update(“biomass”) has been run previously.

premise iterates through activities that consume any of the newly created fuel markets to update the way CO2 emissions are modelled. Based on the fuel market composition, CO2 emissions within the fuel-consuming activity are split between fossil and non-fossil emissions.

The table below shows the example where the CO2 emissions of a 3.5t truck have been split into biogenic and fossil fractions after re-link to the new diesel market of the REMIND region for India.

Output

before

after

_

_

producer

amount

amount

unit

location

transport, freight, lorry, diesel, 3.5t

1

1

ton-kilometer

IND

Input

supplier

amount

amount

unit

location

treatment of tyre wear emissions, lorry

-0.0009

-0.0009

kilogram

RER

market for road maintenance

0.0049

0.0049

meter-year

RER

market for road

0.0041

0.0041

meter-year

GLO

treatment of road wear emissions, lorry

-0.0008

-0.0008

kilogram

RER

market for refrigerant R134a

2.84E-05

2.84E-05

kilogram

GLO

treatment of brake wear emissions, lorry

-0.0005

-0.0005

kilogram

RER

Light duty truck, diesel, 3.5t

1.39E-05

1.39E-05

unit

RER

market for diesel, low-sulfur

0.1854

0.1854

kilogram

IND

Carbon dioxide, fossil

0.5840

0.5667

kilogram

_

Carbon dioxide, non-fossil

0.0000

0.0173

kilogram

_

Nitrogen oxides

0.0008

0.0008

kilogram

_

Nitrogen oxides

0.0003

0.0003

kilogram

_

Geographical mapping

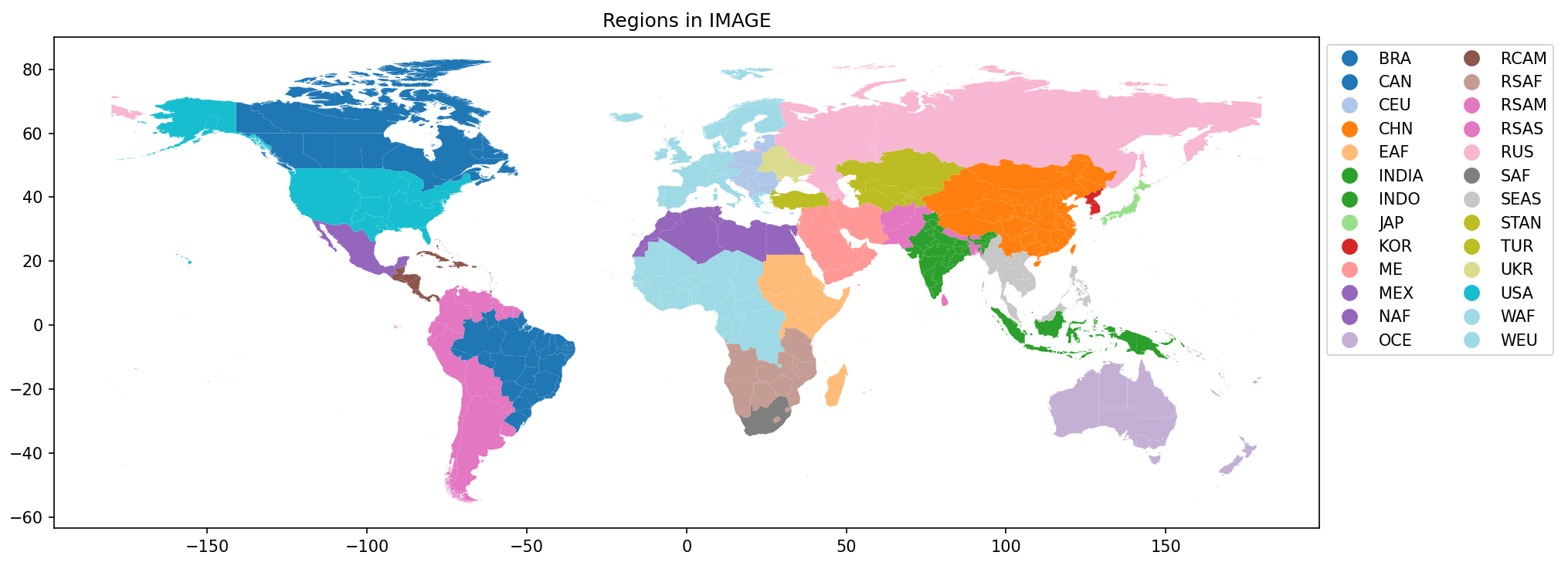

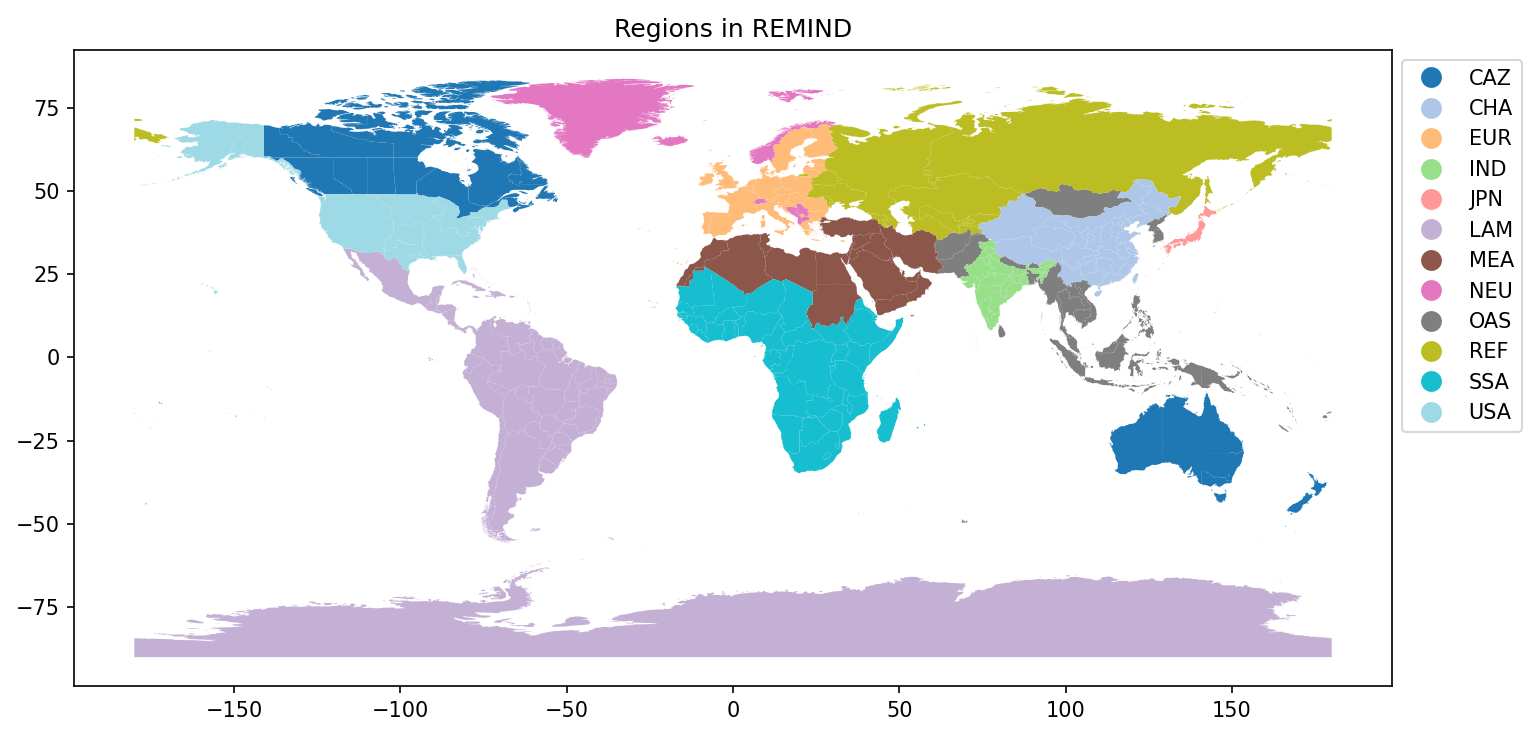

IAM models have slightly different geographical resolutions and definitions.

Map of IMAGE regions

Map of REMIND regions

premise uses the following correspondence between ecoinvent locations and IAM regions. This mapping is performed by the constructive_geometries implementation in the wurst library.

ecoinvent location

REMIND region

IMAGE region

AE

MEA

ME

AL

NEU

CEU

AM

REF

RUS

AO

SSA

RSAF

APAC

OAS

SEAS

AR

LAM

RSAM

AT

EUR

WEU

AU

CAZ

OCE

AZ

REF

RUS

BA

NEU

CEU

BD

OAS

RSAS

BE

EUR

WEU

BG

EUR

CEU

BH

MEA

ME

BJ

SSA

WAF

BN

OAS

SEAS

BO

LAM

RSAM

BR

LAM

BRA

BR-AC

LAM

BRA

BR-AL

LAM

BRA

BR-AM

LAM

BRA

BR-AP

LAM

BRA

BR-BA

LAM

BRA

BR-CE

LAM

BRA

BR-DF

LAM

BRA

BR-ES

LAM

BRA

BR-GO

LAM

BRA

BR-MA

LAM

BRA

BR-MG

LAM

BRA

BR-Mid-western grid

LAM

BRA

BR-MS

LAM

BRA

BR-MT

LAM

BRA

BR-North-eastern grid

LAM

BRA

BR-Northern grid

LAM

BRA

BR-PA

LAM

BRA

BR-PB

LAM

BRA

BR-PE

LAM

BRA

BR-PI

LAM

BRA

BR-PR

LAM

BRA

BR-RJ

LAM

BRA

BR-RN

LAM

BRA

BR-RO

LAM

BRA

BR-RR

LAM

BRA

BR-RS

LAM

BRA

BR-SC

LAM

BRA

BR-SE

LAM

BRA

BR-South-eastern grid

LAM

BRA

BR-Southern grid

LAM

BRA

BR-SP

LAM

BRA

BR-TO

LAM

BRA

BW

SSA

RSAF

BY

REF

UKR

CA

CAZ

CAN

CA-AB

CAZ

CAN

CA-BC

CAZ

CAN

CA-MB

CAZ

CAN

Canada without Quebec

CAZ

CAN

CA-NB

CAZ

CAN

CA-NF

CAZ

CAN

CA-NS

CAZ

CAN

CA-NT

CAZ

CAN

CA-NU

CAZ

CAN

CA-ON

CAZ

CAN

CA-PE

CAZ

CAN

CA-QC

CAZ

CAN

CA-SK

CAZ

CAN

CA-YK

CAZ

CAN

CD

SSA

WAF

CENTREL

EUR

CEU

CG

SSA

WAF

CH

NEU

WEU

CI

SSA

WAF

CL

LAM

RSAM

CM

SSA

WAF

CN

CHA

CHN

CN-AH

CHA

CHN

CN-BJ

CHA

CHN

CN-CQ

CHA

CHN

CN-CSG

CHA

CHN

CN-FJ

CHA

CHN

CN-GD

CHA

CHN

CN-GS

CHA

CHN

CN-GX

CHA

CHN

CN-GZ

CHA

CHN

CN-HA

CHA

CHN

CN-HB

CHA

CHN

CN-HE

CHA

CHN

CN-HL

CHA

CHN

CN-HN

CHA

CHN

CN-HU

CHA

CHN

CN-JL

CHA

CHN

CN-JS

CHA

CHN

CN-JX

CHA

CHN

CN-LN

CHA

CHN

CN-NM

CHA

CHN

CN-NX

CHA

CHN

CN-QH

CHA

CHN

CN-SA

CHA

CHN

CN-SC

CHA

CHN

CN-SD

CHA

CHN

CN-SGCC

CHA

CHN

CN-SH

CHA

CHN

CN-SX

CHA

CHN

CN-TJ

CHA

CHN

CN-XJ

CHA

CHN

CN-XZ

CHA

CHN

CN-YN

CHA

CHN

CN-ZJ

CHA

CHN

CO

LAM

RSAM

CR

LAM

RCAM

CU

LAM

RCAM

CW

LAM

RCAM

CY

EUR

CEU

CZ

EUR

CEU

DE

EUR

WEU

DK

EUR

WEU

DO

LAM

RCAM

DZ

MEA

NAF

EC

LAM

RSAM

EE

EUR

CEU

EG

MEA

NAF

ENTSO-E

EUR

WEU

ER

SSA

EAF

ES

EUR

WEU

ET

SSA

EAF

Europe without Austria

EUR

WEU

Europe without Switzerland

EUR

WEU

Europe without Switzerland and Austria

EUR

WEU

Europe, without Russia and Turkey

EUR

WEU

FI

EUR

WEU

FR

EUR

WEU

GA

SSA

WAF

GB

EUR

WEU

GE

REF

RUS

GH

SSA

WAF

GI

EUR

WEU

GLO

World

World

GR

EUR

WEU

GT

LAM

RCAM

HK

CHA

CHN

HN

LAM

RCAM

HR

EUR

CEU

HT

LAM

RCAM

HU

EUR

CEU

IAI Area, Africa

SSA

RSAF

IAI Area, Asia, without China and GCC

OAS

SEAS

IAI Area, EU27 & EFTA

EUR

WEU

IAI Area, Gulf Cooperation Council

MEA

ME

IAI Area, North America

USA

USA

IAI Area, Russia & RER w/o EU27 & EFTA

REF

RUS

IAI Area, South America

LAM

RSAM

ID

OAS

INDO

IE

EUR

WEU

IL

MEA

ME

IN

IND

INDIA

IN-AP

IND

INDIA

IN-AR

IND

INDIA

IN-AS

IND

INDIA

IN-BR

IND

INDIA

IN-CT

IND

INDIA

IN-DL

IND

INDIA

IN-Eastern grid

IND

INDIA

IN-GA

IND

INDIA

IN-GJ

IND

INDIA

IN-HP

IND

INDIA

IN-HR

IND

INDIA

IN-JH

IND

INDIA

IN-JK

IND

INDIA

IN-KA

IND

INDIA

IN-KL

IND

INDIA

IN-MH

IND

INDIA

IN-ML

IND

INDIA

IN-MN

IND

INDIA

IN-MP

IND

INDIA

IN-NL

IND

INDIA

IN-North-eastern grid

IND

INDIA

IN-Northern grid

IND

INDIA

IN-OR

IND

INDIA

IN-PB

IND

INDIA

IN-PY

IND

INDIA

IN-RJ

IND

INDIA

IN-SK

IND

INDIA

IN-Southern grid

IND

INDIA

IN-TN

IND

INDIA

IN-TR

IND

INDIA

IN-UP

IND

INDIA

IN-UT

IND

INDIA

IN-WB

IND

INDIA

IN-Western grid

IND

INDIA

IQ

MEA

ME

IR

MEA

ME

IS

NEU

WEU

IT

EUR

WEU

JM

LAM

RCAM

JO

MEA

ME

JP

JPN

JAP

KE

SSA

EAF

KG

REF

STAN

KH

OAS

SEAS

KP

OAS

KOR

KR

OAS

KOR

KW

MEA

ME

KZ

REF

STAN

LB

MEA

ME

LK

OAS

RSAS

LT

EUR

CEU

LU

EUR

WEU

LV

EUR

CEU

LY

MEA

NAF

MA

MEA

NAF

MD

REF

UKR

ME

NEU

ME

MG

SSA

EAF

MK

NEU

CEU

MM

OAS

SEAS

MN

OAS

CHN

MT

EUR

WEU

MU

SSA

EAF

MX

LAM

MEX

MY

OAS

SEAS

MZ

SSA

RSAF

NA

SSA

RSAF

NE

SSA

WAF

NG

SSA

WAF

NI

LAM

RCAM

NL

EUR

WEU

NO

NEU

WEU

NORDEL

NEU

WEU

North America without Quebec

USA

USA

NP

OAS

RSAS

NZ

CAZ

OCE

OCE

CAZ

OCE

OM

MEA

ME

PA

LAM

RCAM

PE

LAM

RSAM

PG

OAS

INDO

PH

OAS

SEAS

PK

OAS

RSAS

PL

EUR

CEU

PT

EUR

WEU

PY

LAM

RSAM

QA

MEA

ME

RAF

SSA

RSAF

RAS

CHA

CHN

RER

EUR

WEU

RER w/o CH+DE

EUR

WEU

RER w/o DE+NL+RU

EUR

WEU

RER w/o RU

EUR

WEU

RLA

LAM

RSAM

RME

MEA

ME

RNA

USA

USA

RO

EUR

CEU

RoW

World

World

RS

NEU

CEU

RU

REF

RUS

RW

SSA

EAF

SA

MEA

ME

SAS

IND

INDIA

SD

MEA

EAF

SE

EUR

WEU

SG

OAS

SEAS

SI

EUR

CEU

SK

EUR

CEU

SN

SSA

WAF

SS

SSA

EAF

SV

LAM

RCAM

SY

MEA

ME

TG

SSA

WAF

TH

OAS

SEAS

TJ

REF

STAN

TM

REF

STAN

TN

MEA

NAF

TR

MEA

TUR

TT

LAM

RCAM

TW

CHA

CHN

TZ

SSA

RSAF

UA

REF

UKR

UCTE

EUR

WEU

UCTE without Germany

EUR

WEU

UN-OCEANIA

CAZ

OCE

UN-SEASIA

OAS

SEAS

US

USA

USA

US-ASCC

USA

USA

US-HICC

USA

USA

US-MRO

USA

USA

US-NPCC

USA

USA

US-PR

USA

USA

US-RFC

USA

USA

US-SERC

USA

USA

US-TRE

USA

USA

US-WECC

USA

USA

UY

LAM

RSAM

UZ

REF

STAN

VE

LAM

RSAM

VN

OAS

SEAS

WECC

USA

USA

WEU

EUR

WEU

XK

EUR

CEU

YE

MEA

ME

ZA

SSA

SAF

ZM

SSA

RSAF

ZW

SSA

RSAF

Regionalization

Several of the integration steps described above involve the regionalization of datasets. It is the case, for example, when introducing datasets representing a process for each of the IAM regions. In such case, the datasets are regionalized by selecting the most representative suppliers of inputs for each region. If a dataset in a specific IAM region requires tap water, for example, the regionalization process will select the most representative water suppliers in that region.

If more than one supplier is available, the regionalization process will allocated a supply share to each candidate supplier based on their respective production volume. If no adequate supplier is found for a given region, the regionalization process will select all the existing suppliers and allocate a supply share to each supplier based on their respective production volume.

Here is the decision tree followed:

Decision Tree for Processing Datasets

The process begins with a dataset that requires processing.

Decision: Is the Exchange in Cache?

Yes

Use

process_cached_exchange().Retrieve cached data.

Update

new_exchangeswith cached data.

No

Use

process_uncached_exchange().None

Print a warning and return.

One

Use

handle_single_possible_dataset().Use the single matched dataset.

Update

new_exchangeswith this dataset information.

Multiple

Use

handle_multiple_possible_datasets().Yes

Use the matched dataset location.

No

Use

process_complex_matching_and_allocation().IAM Region

Use

handle_iam_region().Match IAM region to ecoinvent locations.

Update

new_exchangeswith IAM region-specific data.Cache the new entry.

Global (‘GLO’, ‘RoW’, ‘World’)

Use

handle_global_and_row_scenarios().Allocate inputs for global datasets.

Update

new_exchangeswith global data.Cache the new entry.

Others

Perform GIS matching.

Determine intersecting locations with GIS.

Allocate inputs based on GIS matches.

Update

new_exchangeswith GIS-specific data.Cache the new entry.

Final Steps

If no match is found, use

handle_default_option().Integrate new exchanges into the dataset.

GAINS emission factors

Run

from premise import *

import brightway2 as bw

bw.projects.set_current("my_project)

ndb = NewDatabase(

scenarios=[

{"model":"remind", "pathway":"SSP2-Base", "year":2028}

],

source_db="ecoinvent 3.7 cutoff",

source_version="3.7.1",

key='xxxxxxxxxxxxxxxxxxxxxxxxx'

)

ndb.update("emissions")

When using update(“emissions”), emission factors from the GAINS-EU and GAINS-IAM models are used to scale non-CO2 emissions in various datasets.

The emission factors are available under https://github.com/polca/premise/tree/master/premise/data/GAINS_emission_factors

Emission factors from GAINS-EU are applied to activities in European countries. Emission factors from GAINS-IAM are applied to activities in non-European countries, or to European activities if an emission facor from GAINS-EU has not been applied first.

Emission factors are specific to:

an activity type,

a year,